Boring, Pneumatic Tool, Underground Missile, Air Piercing Tool Underground Missile, Underground Missile Air Hole, Mole Pneumatic, Hole Boring Mole Pneumatic, Mole pneumatic boring missilew ith hoses and oilers, Underground Boring equipment, moles - missiles - underground piercing tools, piercing Tool Underground, Tool Underground, Missiles for sale UK, IRELAND

UK, IRELAND SALES DEPARTAMENT: +353 874265440

Mail: biurochrist@gmail.com

https://www.facebook.com/ngsystemwnetrza

Underground Boring Equipment, earth boring equipment, horizontal boring machines, or underground earth boring equipment. Core Boring.

We offer Trenchless Technology, culvert cleaners, bits, pullers and irrigation, fiber optic, pvc and conduit installation ability. We specialize in underground boring.

The fastest, easiest and most cost effective way to install pipe or electrical conduit under sidewalks, driveways, roads and other pavement.

MAX K55 Tool Diameter (In.) / (mm) 2 / 55

MAX K65 Tool Diameter (In.) / (mm) 2 1/2 / 65

MAX K75K Tool Diameter (In.) / (mm) 3 / 75

MAX K75S Tool Diameter (In.) / (mm) 3 / 75

MAX K95S Tool Diameter (In.) / (mm) 3 3/4 / 95

MAX K130S Tool Diameter (In.) / (mm) 5 / 130

MAX K160S Tool Diameter (In.) / (mm) 6 1/4 / 160

MAX K180S Tool Diameter (In.) / (mm) 7 / 180

MAX T24

How it works: By hydraulically driving a counter-weight back and forth inside a cylinder the tool is pushed forward through the ground. As the weight inside the cylinder moves forward it applies pressure to the body of the cylinder to hold it in place. Once the weight strikes the front of the tool it pushes the tool forward a little bit at a time and can usually push any obstacles such as rocks out of the way.

One vital thing is to make sure no underground utilities are in front of or right next to the path of the tool.

Saving time on a water line repair or water line replacement installation cannot come at the expense of utility damage. Our determined new standards in trenchless technology tool market.

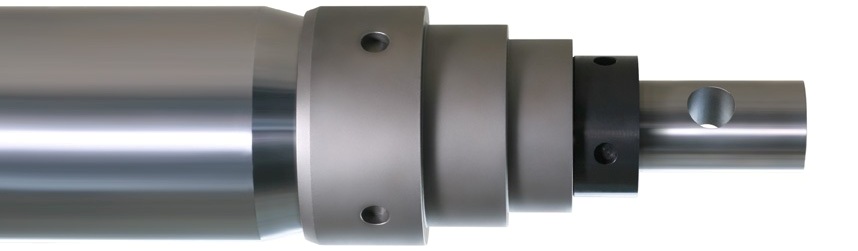

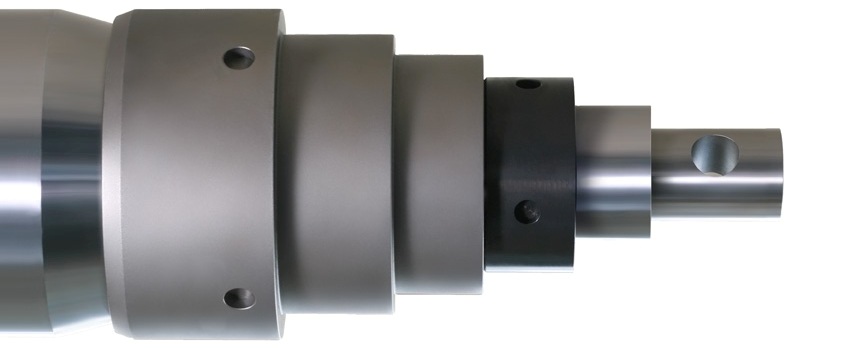

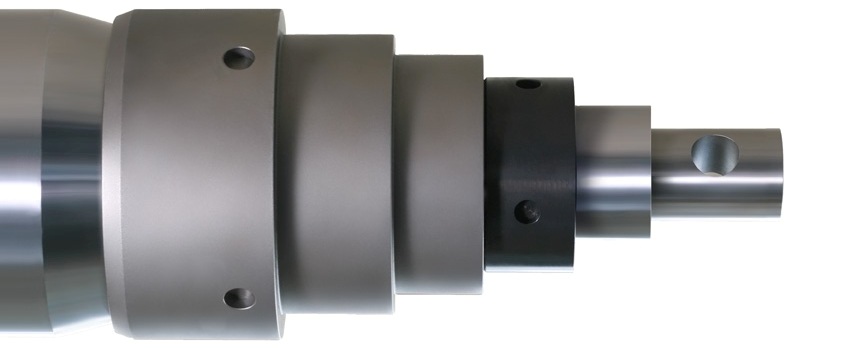

Our moles are equipped with innovate embed of the head, as well as increased weight rams. The unique construction with Teflon technology provides strength, high efficency and durability.

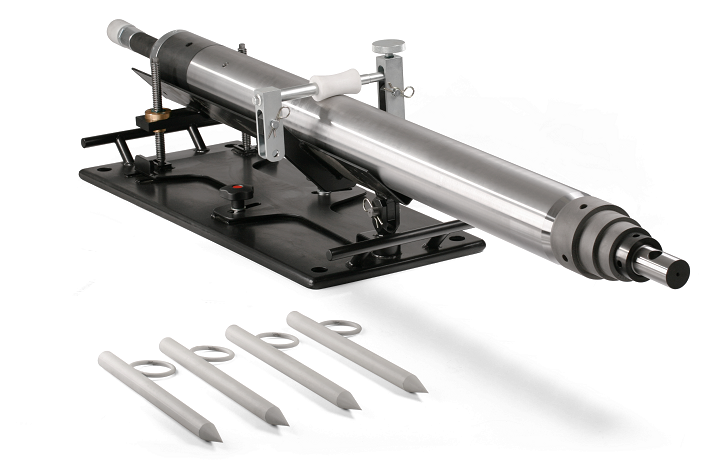

MAX K55

MAX K55 is the smallest and the lightest mole in our offer. Just like other pneumatic moles. MAX K55 has pneumatic changing direction system, which allow to change direction in all ground conditions. MAX K55 is the best choice for making holes for installation pipes diameter Ø32 and Ø40 mm.

APPLICATION:

Make a hole diameter [mm] ø55

Inserting PE, PCV pipes manually with expanding tools [mm] ø25- ø40

TECHNICAL PARAMETERS:

Diameter of the machine [mm]: ø55

Length of the machine [mm]: 1180

Weight [kg]: 15

Compressed air consumption [m3/min.]: from 0,7 (recommended 1,1)

Air pressure [atm]: 7

Basic set include:

MAX K55S mole,

control power supply hose 20 mb,

Lubricator with control panel,

Oil EkoMAX 5l

MAX K65

MAX K65 is very easy to use and very lightweight. As each of our machine, it also has a remote control via a pneumatic valve in lubricator. K65 is very popular in electrical and telecom connections, especially to PE, PCV pipes diameter ø50 mm. As our other machines, K65 has very high precision and speed.

APPLICATION:

Make a hole diameter [mm] ø65

Inserting PE, PCV pipes directly behind the machine [mm] ø50, ø63

Inserting PE, PCV pipes manually with expanding tools [mm] ø25- ø55

TECHNICAL PARAMETERS:

Diameter of the machine [mm]: ø65

Length of the machine [mm]: 1366

Weight [kg]: 22,5

Compressed air consumption [m3/min.]: from 0,8 (recommended 1,2)

Air pressure [atm]: 7

Basic set include:

MAX K65S mole,

control power supply hose 20 mb,

Lubricator with control panel,

Set of tools (2 pcs.).

Oil EkoMAX 5l

Safety and Warranty:

We provide two years of warranty for machines

MAX K75K

MAX K75K is the shorter and lighter version of MAX K75S. MAX K75K is designed for making installation where is the very little space for making installation, especially for starting pit. The reduced length decrease the accuracy of installation, so it is dedicated for shorter distanced installation.

APPLICATION:

Make a hole diameter [mm] ø75

Inserting PE, PCV pipes directly behind the machine [mm] ø63, ø75

Inserting PE, PCV pipes manually with expanding tools [mm] ø25- ø55

TECHNICAL PARAMETERS:

Diameter of the machine [mm]: ø75

Length of the machine [mm]: 1084

Weight [kg]: 22

Compressed air consumption [m3/min.]: from 1,1 (recommended 1,8)

Air pressure [atm]: 7

Basic set include:

MAX K75K mole,

control power supply hose 20 mb,

Lubricator with control panel,

Set of tools (2 pcs.).

Oil EkoMAX 5l

Safety and Warranty:

We provide two years of warranty for machines

MAX K75S

MAX K75S is the best when the most of the work concerns inserting of PE or PCV pipes diameter ø63 mm, which are very popular in electrical and telecom connections. This machine can also be used to install PE or PCV pipes diameter ø75 mm. Despite its small size, the machine can also be controlled remotely by a pneumatic valve in lubricator. K75 is lightweight, easy to use and effective in action.

APPLICATION:

Make a hole diameter [mm] ø75

Inserting PE, PCV pipes directly behind the machine [mm] ø63, ø75

Inserting PE, PCV pipes manually with expanding tools [mm] ø25- ø55

TECHNICAL PARAMETERS:

Diameter of the machine [mm]: ø75

Length of the machine [mm]: 1501

Weight [kg]: 33

Compressed air consumption [m3/min.]: from 1,1 (recommended 1,8)

Air pressure [atm]: 7

Basic set include:

MAX K75S mole,

control power supply hose 20 mb,

Lubricator with control panel,

Set of tools (2 pcs.)

Oil EkoMAX 5l

Safety and Warranty:

We provide two years of warranty for machines

MAX K95S

MAX K95S is the middle-sized pneumatic machine in our offer. We suggest this machine for PE or PCV pipes diameter ø75 or ø90 mm. It is a stronger version of K75S. Change of direction of work is realized by pneumatic valve in control panel. As our other machines, K95 has very high precision and speed. MAX K95S allow to instaling steel pipes, diameter up to 219 mm.

APPLICATIONS:

Make a hole diameter [mm] Ø95, Ø125

Make a hole diameter [mm] Ø125 using Calibrators

Inserting PE, PCV pipes directly behind the machine [mm] ø75, ø90

Inserting PE, PCV pipes manually with expanding tools [mm] ø25- ø55

Installing steel pipes diameter up to ø219 mm

TECHNICAL PARAMETERS:

Diameter of the machine [mm]: ø95

Length of the machine [mm]: 1641

Weight [kg]: 56

Compressed air consumption [m3/min.]: from 1,7 (recommended 2,5)

Air pressure [atm]: 7

Basic set include:

MAX K95S mole,

control power supply hose 20 mb,

Lubricator with control panel,

Set of tools (2 pcs.)

Oil EkoMAX 5l

Safety and Warranty:

We provide two years of warranty for machines

MAX K130S

MAX K130S is the most popular machine in our offer. It is most universal and most frequently used by our customers. It is the best choice for work with PE or PCV tubes diameter ø110 or ø125 and for steel pipes up to ø323mm. K130S has very high precision and speed. Change of direction is very easy, by the pneumatic valve of control panel in lubricator. The machine has excellent quality and durability. For our K130S we can offer most accessories expanded range of work.

APPLICATIONS:

Make a hole diameter [mm] ø 130

Make a hole with expanding tools diameter [mm] ø160, ø180, ø195, ø219

Inserting PE, PCV pipes directly behind the machine [mm] ø90-125

Inserting PE, PCV pipes with additional tools [mm] ø140, ø160, ø180, ø200

Inserting PE, PCV pipes manually with expanding tools [mm] ø25- ø55

Inserting steel tubes with expanding cones up to [mm] ø323

TECHNICAL PARAMETERS:

Diameter of the machine [mm]: ø130

Length of the machine [mm]: 1815

Weight [kg]: 115

Compressed air consumption [m3/min.]: from 2,4 (recommended 3,6)

Air pressure [atm]: 7

Basic set include:

MAX K130S mole,

control power supply hose 20 mb,

Lubricator with control panel,

Set of tools (2 pcs.).

Oil EkoMAX 5l

Safety and Warranty:

We provide two years of warranty for machines

MAX K160S

MAX K160S is the machine for medium and large sized of installation. It is designed for pulling PE/PVC pipes diameter Ø110, Ø125, Ø140 and Ø160 mm in the first operation. Also it is very useful for installation form steel pipes diameter up to Ø406 mm. MAX K160S has the same advantages like other our products. It is easy to use and control. It has a great efficiency and accuracy.

APPLICATIONS:

Make a hole diameter Ø160mm

Make a hole with expanding tools diameter [mm] ø195, ø219

Inserting PE/PVC pipes diameter directly behind the machine Ø110 - 140 mm

Inserting PE/PVC pipes Ø160 - 200 mm using accessories

Inserting steel tubes with expanding cones [mm] up to ø406

TECHNICAL PARAMETERS:

Diameter of the machine - 160 mm

Length of the machine - 2110 mm

Weight - 203 kg

Working pressure - 7 atm

Compressed air consumption - from 3,5 m3/min (recommended 4,5)

Frequency - 6 Hz

Basic set include:

MAX K160S mole,

control power supply hose 20 mb,

Lubricator with control panel,

Set of tools (2 pcs.).

Oil EkoMAX 5l

MAX K180S

MAX K180S is designed for pulling plastic pipes ø160 mm, and also for installing steel pipes up to ø400 mm. The main advantages are excellent quality and durability, high precision and speed. The machine is very easy in use, the direction of work can be realized by pneumatic valve located in lubricator. Accessories for K180 are compatible with accessories for our other machines.

APPLICATIONS:

Make a hole diameter [mm] ø 180

Make a hole with expanding tools diameter [mm] ø219, ø244

Inserting PE, PVC pipes directly behind the machine [mm] ø140-ø160

Inserting PE, PVC pipes [mm] ø180-ø225 using accessories

Inserting steel tubes with expanding cones [mm] up to ø406

TECHNICAL PARAMETERS:

Diameter of the machine [mm]: ø180

Length of the machine [mm]: 2256

Weight [kg]: 275

Compressed air consumption [m3/min.]: from 4,5 (recommended 5,0)

Air pressure [atm]: 7

Basic set include:

MAX K180S mole,

control power supply hose 20 mb,

Lubricator with control panel,

Set of tools (2 pcs.).

Oil EkoMAX 5l

Safety and Warranty:

We provide two years of warranty for machines

MAX T240

MAX T240 is a machine designed for inserting steel pipes to the diameter up to ø600 mm. The innovative construction ensures a very high impact power, 40-60% higher than in other machines of this type of similar weight and sizes.

MAX Impact Power T240

MAX Impact Power LUBRICATOR

Application:

Ramming steel pipes diameter up to 711 mm

Features of the MAX T240:

the best relationship between air consumption, sizes and power

high durability and reliability,

easy to use

low operating costs

work at low temperatures

TECHNICAL PARAMETERS:

Inserting steel tubes with expanding cones up to [mm] ø711

Diameter of the machine [mm] ø240

Length of the machine [mm] 1630

Weight [kg] 380

Compressed air consumption [m3/min.] from 6,0 – 7,5

Air pressure [atm] 6

Frequency [Hz] 1,7 – 2,5

Impact energy at a pressure 6 atm [J] 2000

Basic set includes:

MAX T240 hammer,

cones for inserting steel pipes 219,1 – 323,9; 406,4; 508,

lubricator

power supply hose

connector to air compressor

mounting kit

set of tools (2

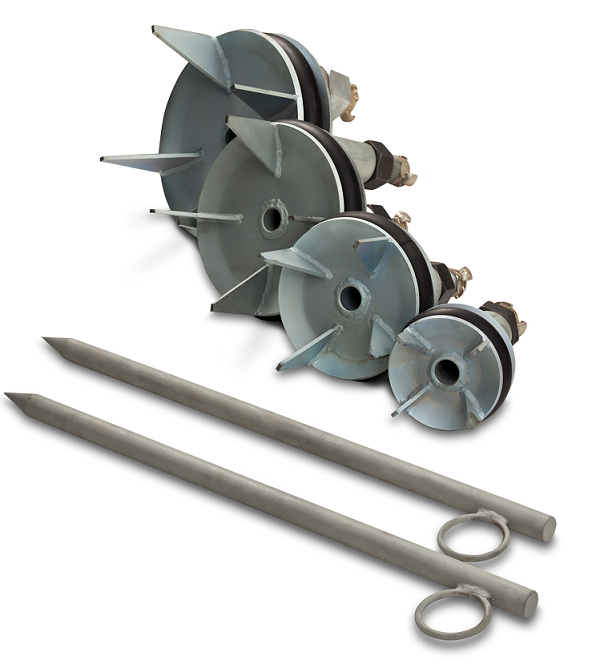

Accessories

I. For inserting PE or PCV pipes:

SLEEVES FOR INSERTING PLASTIC PIPES

TENSIONER TO THE ROPE WITH STEEL ROPE AND FLANGES

TIP FOR INSERTING PLASTIC PIPES MANUALLY

II. For inserting steel pipes:

CONES FOR INSERTING STEEL PIPES

III. For removing sand from installed steel pipes:

TOOLS FOR REMOVING SAND FROM INSERTED STEEL PIPES

PNEUMATIC HOSE FOR CENNECTING REMOVAL TOOLS WITH COMPRESSOR

VI. Accessories for expanding diameret of machines:

CALIBRATORS FOR

EXPANDING THE HOLES

AND INSERTING PIPES

WIDER THAN THE

DIAMETER OF MACHINE

TOWING ELEMENTS

V. Accessories for adjusting pneumatic moles:

STARTING PLATFORM

OPTICAL SET

VI. Others:

EKOLOGICAL OIL

FOR LOBRICATING

CONTROL STATION

/ LUBRICATOR

Boring, Pneumatic, Tool Underground Missile Air, Piercing Tool Underground Missile, Underground Missile Air Hole, Mole Pneumatic, Hole Boring Mole Pneumatic, Piercing Tool Underground, Tool Underground, Missile,

Most Viewed

Mole Pneumatic boring missile 5 1/4" Piercing Tool piercing tool, Mole Pneumatic boring missile 4" Piercing Tool piercing tool, Vermeer Ditch Witch underground boring piercing, mole missile 3", Mole Pneumatic boring missile 3" Piercing Tool piercing tool, Vermeer 2.5" Piercing Tool Underground Missile Air Hole Boring Mole Pneumatic h, Hole Boring Mole Pneumatic 3" Piercing Tool Underground Missile Air, Pneumatic Pipe Bursting Piercing Mole Boring Tool Reversible 2-3/16", Hole Boring Mole Pneumatic 2 1/2" Piercing Tool Underground Missile Air, GRUNDOMAT VERMEER DITCH WITCH 2.5" HOLE BORING UNDERGROUND MOLE PIERCING MISSILE, PIERCING TOOL MOLE PNEUMATIC HORIZONTAL BORING HAMMERHEAD MISSILE GRUNDOMAT, Vermeer Ditch Witch underground boring piercing, mole missile 3", Hole Boring Mole Pneumatic 2 5/8" Piercing Tool Underground Missile Air,

TECHNOLOGY.

JDS FIBER OPTIC STRUCTURAL CABLING, OUTSITE PLANT TELECOMUNICATION INSTALLATIONS ENGENEERING, AIR BLOWN FIBER OPTIC CABLING, CABLE GANG, Boring, Pneumatic, Tool Underground Missile Air, Piercing Tool Underground Missile, Underground Missile Air Hole, Mole Pneumatic,

JDS FIBER OPTIC STRUCTURAL CABLING, OUTSITE PLANT TELECOMUNICATION INSTALLATIONS ENGENEERING, AIR BLOWN FIBER OPTIC CABLING, CABLE GANG, Boring, Pneumatic, Tool Underground Missile Air, Piercing Tool Underground Missile, Underground Missile Air Hole, Mole Pneumatic,

JDS FIBER OPTIC STRUCTURAL CABLING, OUTSITE PLANT TELECOMUNICATION INSTALLATIONS ENGENEERING, AIR BLOWN FIBER OPTIC CABLING, CABLE GANG, Boring, Pneumatic, Tool Underground Missile Air, Piercing Tool Underground Missile, Underground Missile Air Hole, Mole Pneumatic,

JDS OUTSITE PLANT FIBER OPTIC CABLING, Boring, Pneumatic, Tool Underground Missile Air, Piercing Tool Underground Missile, Underground Missile Air Hole, Mole Pneumatic, Hole Boring Mole Pneumatic, Piercing Tool Underground

JDS OUTSITE PLANT FIBER OPTIC CABLING, Boring, Pneumatic, Tool Underground Missile Air, Piercing Tool Underground Missile, Underground Missile Air Hole, Mole Pneumatic, Hole Boring Mole Pneumatic, Piercing Tool Underground

JDS OUTSITE PLANT FIBER OPTIC CABLING, Boring, Pneumatic, Tool Underground Missile Air, Piercing Tool Underground Missile, Underground Missile Air Hole, Mole Pneumatic, Hole Boring Mole Pneumatic, Piercing Tool Underground

Jacek Data Fibre Cable Blowing.

Obsługa inwestycji światłowodowych. Projektowanie, budowa, pomiary

Potencjał pozwalający na przebudowę czynnych kabli (jednoczesna praca wykorzystując 4 spawarki równocześnie)

Nasza firma pomaga inwestorom w doborze odpowiedniego sprzętu tak aby bez problemów osiągnąć zamierzone cele.

Oferujemy Państwu pełen pakiet obsługi poprzez:

Doświadczenie zdobywane od 2001 roku na ponad 100 budowach. Gwarancja 24 miesięcy. serwis 24h

Jednym z najważniejszych aspektów wykonanej inwestycji jest jakość.

W celu zapewnienia najlepszych standardów firma posiada najwyższej klasy sprzęt do wykonania inwestycji.

Oferujemy kompleksową realizację sieci światlowodowych. Zakres prac:

Montaż Światłowodów,

Wstrzeliwanie światłowodu

Wdmuchiwanie kabli światłowodowych

Trakcje światłowodowe

Sieci światłowodowe

Budowa linii światłowodowych

osprzęt światłowodowy i spawanie światłowodów

złącza i konwertery światłowodowe i światłowody

Wciąganie kabla światłowodowego do rurociągu kablowego z rury HDPE

Budowa przyłączy światłowodowych

Aktywne urządzenia sieciowe do sieci strukturalnych i telekomunikacyjnych,

Wklejanie złączy, pomiary transmisji światłowodowych, wykonywanie patchcordów

Obsługa trudnych i nietypowych prac, takich jak przebudowy węzłów optycznych

Spawanie światłowodów wielo i jednomodowych SM i MM oraz pomiary miernikiem mocy i reflektometrem optycznym OTDR

Realizacja sieci światlowodowych napowietrznych (budując nowe trakcje bądź wykorzystując istniejącą infrastrukturę),

Realizacja sieci światlowodowych podziemnych (budując trasy światłowodowe z wykorzystaniem mediów miedzianych, kanalizacji pierwotnej bądź wtórnej),

Realizacja sieci światlowodowych podwodnych (wykonując połączenia na małych i średnich głębokościach),

Wdmuchiwanie światłowodów – technika pozwalająca na wprowadzanie kabli lub mikrokabli światłowodowych w rury osłonowe.

Wdmuchiwanie kabli polega na wprowadzaniu kabla w rurę osłonową w strumieniu sprężonego powietrza lub wody. Przepływające medium wykorzystując tarcie o powierzchnię kabla powoduje jego przemieszczanie się. Dodatkowa siła pochodząca od podajnika mechanicznego wpychającego kabel pozwala na wdmuchnięcie go na znaczne odległości. Kabel przemieszcza się w rurze osłonowej tak długo, aż opory tarcia nie zrównoważą sił ciągnącej (od powietrza) i pchającej (podajnik). Zmniejszenie oporów tarcia uzyskuje się dzięki stosowaniu płynów poślizgowych. W warunkach polskich udaje się wdmuchiwać odcinki kabli o długości do 2 500 m. Rozróżniamy trzy odmiany tej techniki.

Specjalizujemy się w pełnej obsłudze urządzeń infrastruktury obiektów. Realizujemy naprawy gwarancyjne jak i pogwarancyjne a także świadczymy usługi kompleksowej opieki konserwacyjnej.

Doświadczenie zdobywane od 2001 roku na ponad 100 budowach. Gwarancja 24 miesięcy. serwis 24h

Jednym z najważniejszych aspektów wykonanej inwestycji jest jakość.

W celu zapewnienia najlepszych standardów firma posiada najwyższej klasy sprzęt do wykonania inwestycji.

05-520 Konstancin-Jeziorna, ul. Mirkowska 10, tel.: 789337400, e-mail: biuro.washme@gmail.com

Systemy gaszenia gazami neutralnymi,

Automatyczne Systemy Gaszenia Ognia,

instalacje teletechniczne,

systemy wczesnego wykrywania dymu,

gazowe systemy gaszenia ognia,

Systemy sygnalizacji alarmu pożarowego,

Dźwiękowe Systemy Ostrzegawcze,

Stałe urządzenia gaśnicze gazowe,

Systemy wczesnej detekcji pożaru,

Systemy oddymiania grawitacyjnego,

Systemy zamknięć ogniowych,

Systemy sygnalizacji włamania i napadu,

Systemy kamer przemysłowych CCTV,

Systemy przyzywowe,

System przeciwpożarowy – jego zadaniem jest ochrona ludzi i mienia przed zagrożeniami pożarowymi. Prosty system przeciwpożarowy składa się z detektorów ognia, centrali sterującej oraz siatki rur ze środkiem gaśniczym wraz z dyszami wylotowymi (np. stałe urządzenie gaśnicze).

Można wymienić 4 główne rodzaje systemów przeciwpożarowych ze względu na środek gaśniczy:

gaszenie wodą

Jest to automatyczny systemem gaszenia pożaru, bezpośrednio nad miejscem wybuchu ognia, co skutecznie chroni budynek zarówno przed całkowitym spłonięciem jak również przed zalaniem wodą pozostałej jego części i zniszczenie mienia.

W instalacji utrzymywane jest stałe ciśnienie wody, więc w przypadku pożaru, na skutek oddziaływania temperatury na ampułkę tryskacza następuje jego otwarcie i wyzwolenie czynnika gaśniczego, bezpośrednio na źródło zagrożenia. Otwierają się tylko tryskacze znajdujące się bezpośrednio w strefie ognia, co minimalizuje zakres szkód spowodowanych działaniem wody. Przepływająca przez zawór kontrolno-alarmowy woda uruchamia dzwon alarmowy, a czujniki ciśnienia alarmujące o pożarze, automatycznie uruchamiają pompę tryskaczową. Woda tłoczona jest do systemu ze zbiornika wody przeciwpożarowej.

gaszenie mgłą wodną

gaszenie pianą

gaszenie gazem

Jedne z najbardziej popularnych systemów stosowane w serwerowniach i data center z uwagi na swe właściwości. Nie przewodzą prądu i nie niszczą chronionych urządzeń, tak jak byłoby w przypadku wody. W Polsce szeroko stosowane są obojętne gazy gaśnicze typu FE-36 i FM-200.

Realizacje Obiekty publiczne:

MALACHIT Medical Spa Hotel, Karpacz

Salt Quelle Wien, Wien

Oceaneum, Wien

Bayersoien ParkHotel

Salarium - Wellness Center, Karlsruhe

Die Wellness - Insel, Lübeck, Lübeck

Ośrodek Szkoleniowo- Wypoczynkowy "TADEUSZ” w Krynicy Zdrój , Krynica- Zdrój

Ośrodek Szkoleniowo- Wypoczynkowy “REGLE” w Wiśle, Wisła

Europejskie Centrum Rehabilitacji i Odnowy Biologicznej AFRODYTA SPA ***

Hotel Perła Południa - PBM Południe Tour Sp. z o., Rytro

Hotel Klimek SPA, Muszyna

Sanatorium Uzdrowiskowe “RAFAŁ”, Busko Zdrój

Wojewódzkie Centrum Pediatrii Szpital Kubalonka w Istebnej, Istebna

Centrum Rekreacji Sport Factory, Bydgoszcz

Hotel Warszawa, Augustów

Hotel “MALACHIT”- Interferie, Świeradów Zdrój

Aqua Park - “Nemo Wodny Świat “, Dąbrowa Górnicza

Ośrodek Przygotowań Olimpijskich w Spale, Inowłódź

Sanatorium “Metalowiec 70, Inowrocław

The Paulinum Palace, Jelenia Góra

Hotel Malachit Medical Spa, Karpacz

Jelenia Struga Spa Resort, Kowary

Hotel “Stary” - Likus Holding, Kraków

Sanatorium Marta, Połczyn Zdrój

Basen w Ropczycach

Hotel Faltom, Rumia

Hotel Malinowy zdroj sPA, Solec Zdrój

Hotel Villa Hercules, Świnoujście

Hotel Alga, Świnoujście

|

| Systemy wykrywania, gaszenia ognia, pożaru, Systemy sterowania automatycznym gaszeniem pożarów, Systemy sygnalizacji pożaru, zabezpieczenia przeciwpożarowe, |

|

| Systemy wykrywania, gaszenia ognia, pożaru, Systemy sterowania automatycznym gaszeniem pożarów, Systemy sygnalizacji pożaru, zabezpieczenia przeciwpożarowe, |

|

| Systemy wykrywania, gaszenia ognia, pożaru, Systemy sterowania automatycznym gaszeniem pożarów, Systemy sygnalizacji pożaru, zabezpieczenia przeciwpożarowe, |

|

| Systemy wykrywania, gaszenia ognia, pożaru, Systemy sterowania automatycznym gaszeniem pożarów, Systemy sygnalizacji pożaru, zabezpieczenia przeciwpożarowe, |

|

| Systemy wykrywania, gaszenia ognia, pożaru, Systemy sterowania automatycznym gaszeniem pożarów, Systemy sygnalizacji pożaru, zabezpieczenia przeciwpożarowe, |

systemy gaszenia gazem serwerowni

systemy gaszenia serwerowni, systemy gaszenia gazem serwerowni, System gaszenia serwerowni, Systemy gaszenia gazami neutralnymi, Automatyczne Systemy Gaszenia Ognia, gazowe systemy gaszenia ognia. systemy gaszenia gazem serwerowni

systemy gaszenia serwerowni, systemy gaszenia gazem serwerowni, System gaszenia serwerowni, Systemy gaszenia gazami neutralnymi, Automatyczne Systemy Gaszenia Ognia, gazowe systemy gaszenia ognia. systemy gaszenia gazem serwerowni

systemy gaszenia serwerowni, systemy gaszenia gazem serwerowni, System gaszenia serwerowni, Systemy gaszenia gazami neutralnymi, Automatyczne Systemy Gaszenia Ognia, gazowe systemy gaszenia ognia. systemy gaszenia gazem serwerowni

systemy gaszenia serwerowni, systemy gaszenia gazem serwerowni, System gaszenia serwerowni, Systemy gaszenia gazami neutralnymi, Automatyczne Systemy Gaszenia Ognia, gazowe systemy gaszenia ognia. systemy gaszenia gazem serwerowni

systemy gaszenia serwerowni, systemy gaszenia gazem serwerowni, System gaszenia serwerowni, Systemy gaszenia gazami neutralnymi, Automatyczne Systemy Gaszenia Ognia, gazowe systemy gaszenia ognia. systemy gaszenia gazem serwerowni

systemy gaszenia serwerowni, systemy gaszenia gazem serwerowni, System gaszenia serwerowni, Systemy gaszenia gazami neutralnymi, Automatyczne Systemy Gaszenia Ognia, gazowe systemy gaszenia ognia. systemy gaszenia gazem serwerowni

systemy gaszenia serwerowni, systemy gaszenia gazem serwerowni, System gaszenia serwerowni, Systemy gaszenia gazami neutralnymi, Automatyczne Systemy Gaszenia Ognia, gazowe systemy gaszenia ognia. systemy gaszenia gazem serwerowni

systemy gaszenia serwerowni, systemy gaszenia gazem serwerowni, System gaszenia serwerowni, Systemy gaszenia gazami neutralnymi, Automatyczne Systemy Gaszenia Ognia, gazowe systemy gaszenia ognia. .systemy gaszenia gazem serwerowni

systemy gaszenia serwerowni, systemy gaszenia gazem serwerowni, System gaszenia serwerowni, Systemy gaszenia gazami neutralnymi, Automatyczne Systemy Gaszenia Ognia, gazowe systemy gaszenia ognia. systemy gaszenia gazem serwerowni

systemy gaszenia serwerowni, systemy gaszenia gazem serwerowni, System gaszenia serwerowni, Systemy gaszenia gazami neutralnymi, Automatyczne Systemy Gaszenia Ognia, gazowe systemy gaszenia ognia. systemy gaszenia gazem serwerowni

systemy gaszenia serwerowni, systemy gaszenia gazem serwerowni, System gaszenia serwerowni, Systemy gaszenia gazami neutralnymi, Automatyczne Systemy Gaszenia Ognia, gazowe systemy gaszenia ognia. systemy gaszenia gazem serwerowni

systemy gaszenia serwerowni, systemy gaszenia gazem serwerowni, System gaszenia serwerowni, Systemy gaszenia gazami neutralnymi, Automatyczne Systemy Gaszenia Ognia, gazowe systemy gaszenia ognia. systemy gaszenia gazem serwerowni

systemy gaszenia serwerowni, systemy gaszenia gazem serwerowni, System gaszenia serwerowni, Systemy gaszenia gazami neutralnymi, Automatyczne Systemy Gaszenia Ognia, gazowe systemy gaszenia ognia. systemy gaszenia gazem serwerowni

systemy gaszenia serwerowni, systemy gaszenia gazem serwerowni, System gaszenia serwerowni, Systemy gaszenia gazami neutralnymi, Automatyczne Systemy Gaszenia Ognia, gazowe systemy gaszenia ognia. systemy gaszenia gazem serwerowni

systemy gaszenia serwerowni, systemy gaszenia gazem serwerowni, System gaszenia serwerowni, Systemy gaszenia gazami neutralnymi, Automatyczne Systemy Gaszenia Ognia, gazowe systemy gaszenia ognia. systemy gaszenia gazem serwerowni

systemy gaszenia serwerowni, systemy gaszenia gazem serwerowni, System gaszenia serwerowni, Systemy gaszenia gazami neutralnymi, Automatyczne Systemy Gaszenia Ognia, gazowe systemy gaszenia ognia. systemy gaszenia gazem serwerowni

systemy gaszenia serwerowni, systemy gaszenia gazem serwerowni, System gaszenia serwerowni, Systemy gaszenia gazami neutralnymi, Automatyczne Systemy Gaszenia Ognia, gazowe systemy gaszenia ognia.